As the Piwis 3

for Porsche diagnostic & programming released, most client inquiry

for the Piwis 3 to replace Piwis tester ii for Porsche new models. Some

client asks what’s the difference between Piwis Tester II & Piwis 3.

whether the Piwis II work with the Piwis 3 software?

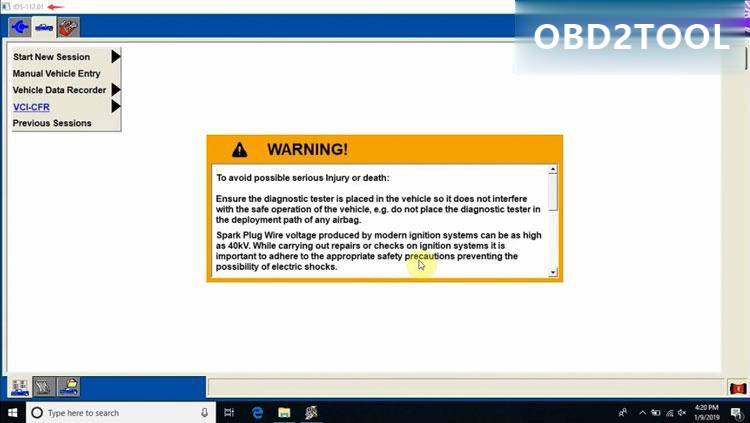

The Piwis 3

The Porsche software starts automatically, but the Microsoft button

functions and you can do other things at the same time such as

TeamViewer or open an internet page. The VCI ( the part that connects to

the diagnostic port) is smaller and the cable connecting is shorter,

but it is a standard USB to miniUSB cable so you can purchase an longer

one anywhere.

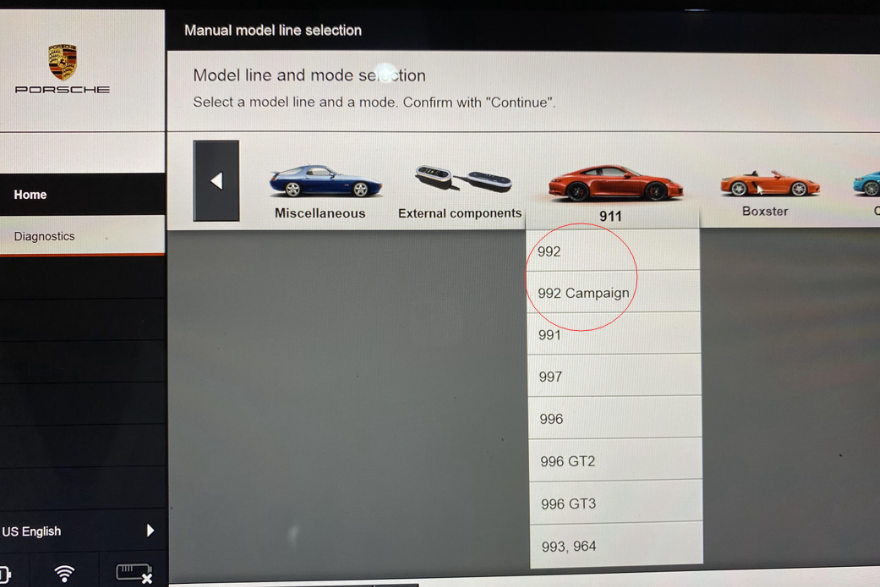

The Porsche Piwis 3 Tester III can be changed from after sales mode

to developer mode which allows for a lot of special features ( looking

at you who want to disable start stop permanently). The software

installed on a SSD, is work faster and easier to use than the previous

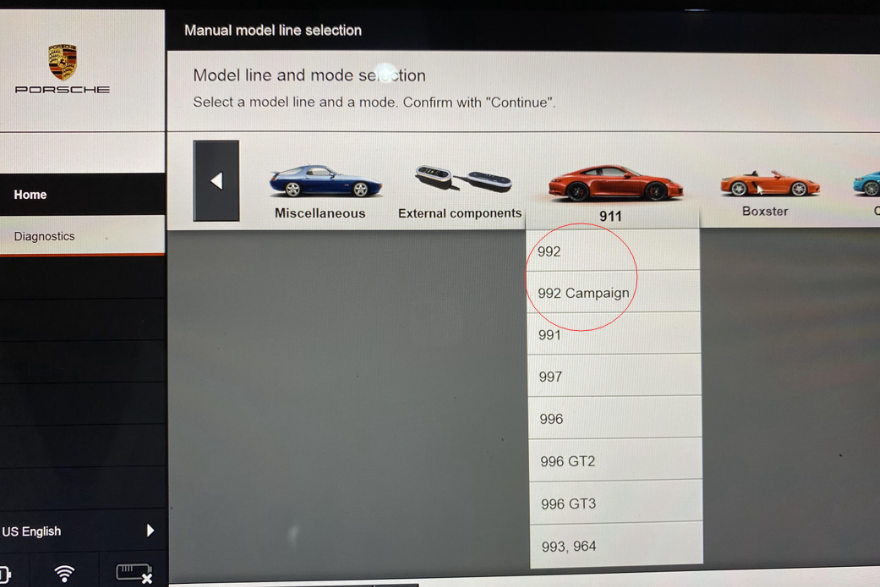

version. For example on the diagnostic program, the tester auto detects

the car model. Just plug it in, turn the key on and it does its thing.

For me, I’m not sure if it is a function of the unit I have or not but

the guided fault finding works well. Click on any fault and press the

fault finding button and the unit tries to provide you a diagnostic

plan. The plan is better and the English description is better. I

haven’t tried the wiring diagram software but I imagine it works as well

as the previous version. There is a new ODBC program on the unit that

reads standard ODBC codes, I am wondering if this unit can be used for

other cars for simple code reading. I will try it on a buddy’s car next

week and let you know. There is a oscilloscope function and a multimeter

function but the laptop clones don’t come with these cables. If you

check out the link I added you can see a factory tool and what that kit

contains as compared to a laptop clone with VCI. All in all it is a

better tool but really can’t do more than the piwis tester 2 can do,

only faster and on cars from model year 2018 to current which the

Porsche diagnostic tool Piwis 2 can’t do.

What Do the Piwis 3 updates replace Piwis 2?

Diagnostics application is used for communication with control units.

You can search for, identify, code and control program units, read out

the event memory, execute complex processes, change drive links and

execute routines.

Guided fault finding (GFF) generates a test plan for a fault code.

This test plan shows the best sequence for carrying out tests. GFF

compiles a list of recommended tests, documents and wiring diagrams

Actual values/input signals functions display you the actual values and input signals of control units

Drive links/tests function displays the drive links of control units,

allows you to change the parameters of these drive links and run test

routines for individual control units

Maintenance/repairs function group – use this function to call up

control unit-specific processes that cannot be implemented generically

from the ODX data

Coding/programming function group – use this function to write coding

values. Piwis 3 can code Values automatically or set manually. This

function group includes (Automatic coding, Manual

coding, Customer-specific settings, and Factory settings) coding modes

Logging – use this function to activate logging for diagnostics,

guided fault finding (GFF) and measuring equipment applications.

Temporary and permanent working log can be created

Filter – use this function to limit the view of the control units

installed in the vehicle. In the diagnostic application, you can create,

edit, activate, deactivate or assign filters

Wiring diagrams application is the representation of physical connections and layouts of circuits

Measuring equipment interface work for DC and AC voltage measurement,

direct and alternating current measurement, diode testing, resistance

measurement, continuity/open circuit testing, showing voltage, current

and resistance over time (oscilloscope function)