Programming Parameter

CAT Caterpillar ET Diagnostic Tool can

be used to view certain parameters that can affect the operation of the

engine. The Cat ET can also be used to change certain parameters. The

parameters are stored in the ECM. Some of the parameters are protected

from unauthorized changes by passwords. Parameters that can be changed

have a tattletale number. The tattletale number shows if a parameter has

been changed.

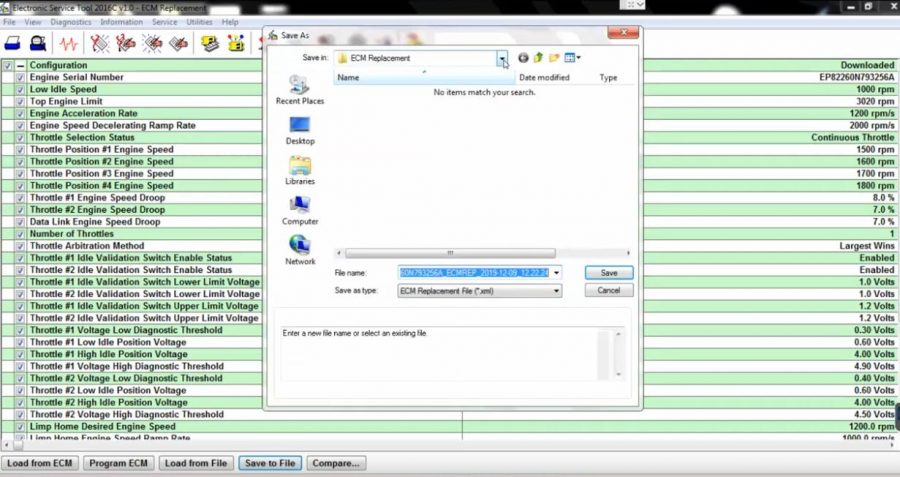

Always document the parameters and the settings that are programmed

into the engine control. A permanent record is essential when customer

programmable parameters must be recovered.

Passwords

Passwords are part of a security system that helps to prevent

unauthorized reprogramming of certain parameters. Passwords prevent

unauthorized erasing of logged events. Passwords allow the factory to

control access to engine calibration parameters. Passwords allow the

customer to control access to certain programmable engine parameters.

Customer Passwords

Customer Passwords allow the customer to restrict access to parameters

that are programmable by the customer. The Customer Passwords cannot be

longer than eight characters. The customer has the option of entering

one or two Customer Passwords.

Note: If the owner loses the owner Customer Passwords, the owner will

not be able to program parameters that are protected by Customer

Passwords. Customer Passwords can be read if a factory password is

obtained. Use those customer passwords to program parameters that have

been protected by the Customer Passwords. But usually, you can directly

edit the parameter as range value (Security: Customer).

Factory Passwords

Factory Passwords are required to clear any event code. Factory

Passwords are required to change certain parameters such as full load

setting (FLS). The Factory Passwords restrict changes to authorized

personnel. When the correct Factory Passwords have been entered, the

changes can then be made. In order to obtain the proper Factory

Passwords, certain information must be given to an authorized

Caterpillar dealer. Since the Factory Passwords contain alphabetic

characters, Cat ET can be used to perform this function. In order to

obtain the Factory Passwords, proceed as if you already have the Factory

Passwords. If the Factory Passwords are needed, Cat ET will request the

Factory Passwords. Cat ET will display the information that is required

to obtain the Factory Passwords (as Figure 1.1 above).

Note: The old interlock code is required to change the interlock code

on a used ECM. A new interlock code is also required to change the

interlock code on a used ECM.

The Cat ET screen for factory passwords will display the following parameters:

Serial Number of the ECM

Engine Serial Number

Serial Number for Cat ET

Reason Code

Total Tattletale Number

Monitoring System (Software Dependent)

Note: The factory passwords may only be used for one programming

session. A different set of factory passwords will be required after you

exit the Cat ET screen. A different set of passwords will be required

to change information on another Cat ET screen.

Feel FREE to Contact Us, if the Factory Passwords are needed (All Cat ET version).

Click on “Save to File” button, then send your “html” file to my e-mail (for 10 digits Factory Passwords only).

Note: Changing the parameters that are protected by Factory Passwords may cause your Caterpillar warranty to be voided.